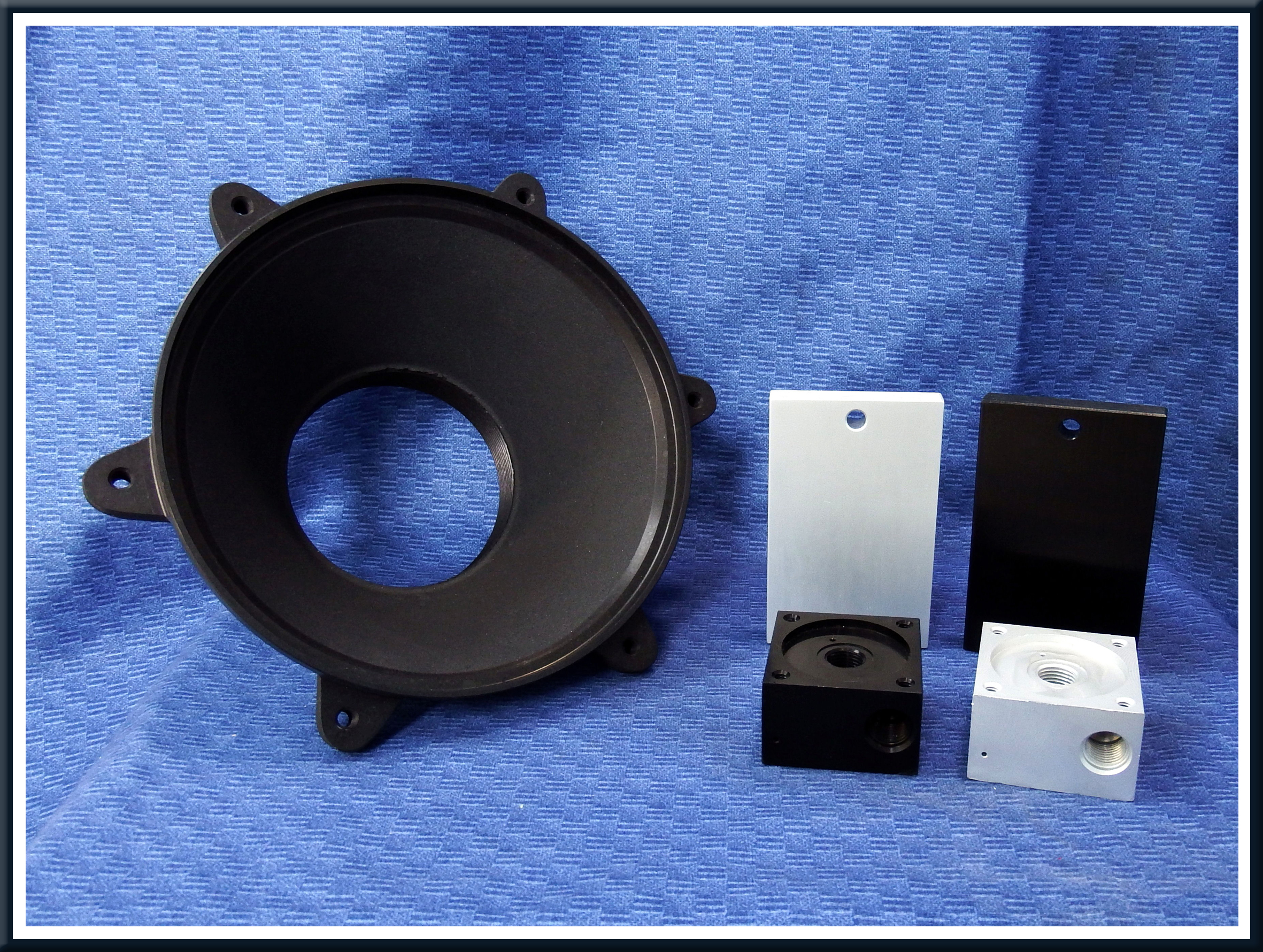

Anodised finishes have helped aluminium become one of the most respected and widely used materials in the production of countless consumer, commercial and industrial products. Functional anodising improves corrosion resistance, wear resistance, provides better adhesion for paint primers and glues, and helps prevent galling on threaded components.

Our sulphuric anodising line is particularly efficient at handling smaller components in large batch sizes but, as always, we have a flexible attitude and are willing to help our customers.

What is Anodising?

Aluminium will naturally oxidise in the atmosphere producing a white powdery layer at the metal surface. This layer will limit any further atmospheric attack by acting as a barrier layer. Anodising is a closely controlled electro-chemical process that mimics this natural process and converts the metal surface into a decorative, durable, corrosion resistant, oxide layer. There is no risk of adhesion failure as the conversion coating is integrated with the underlying aluminium. Most anodised products have an extremely long life span with reduced maintenance and operating costs, offering significant economic advantages.